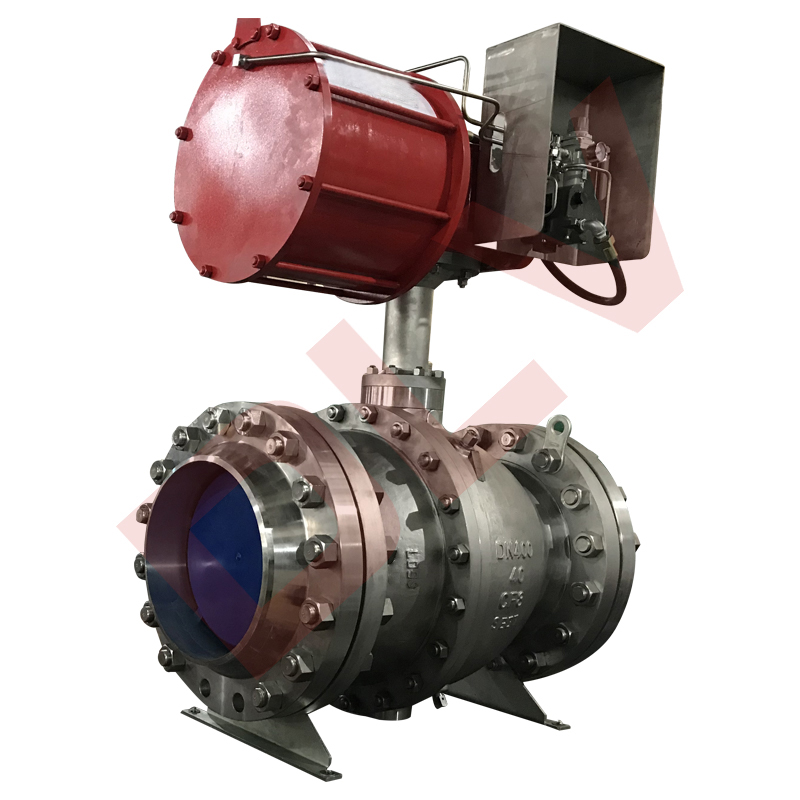

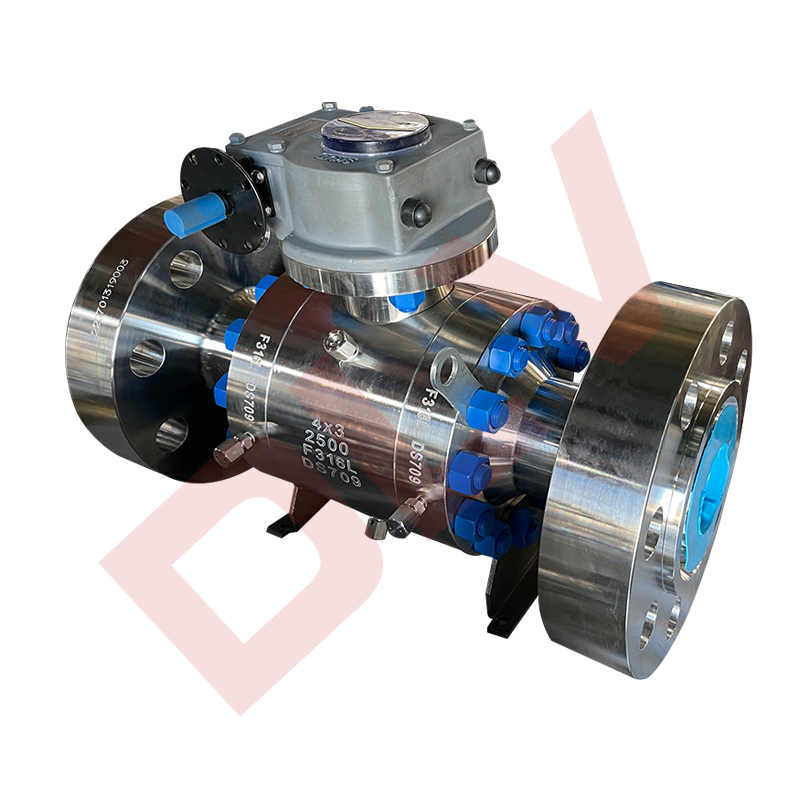

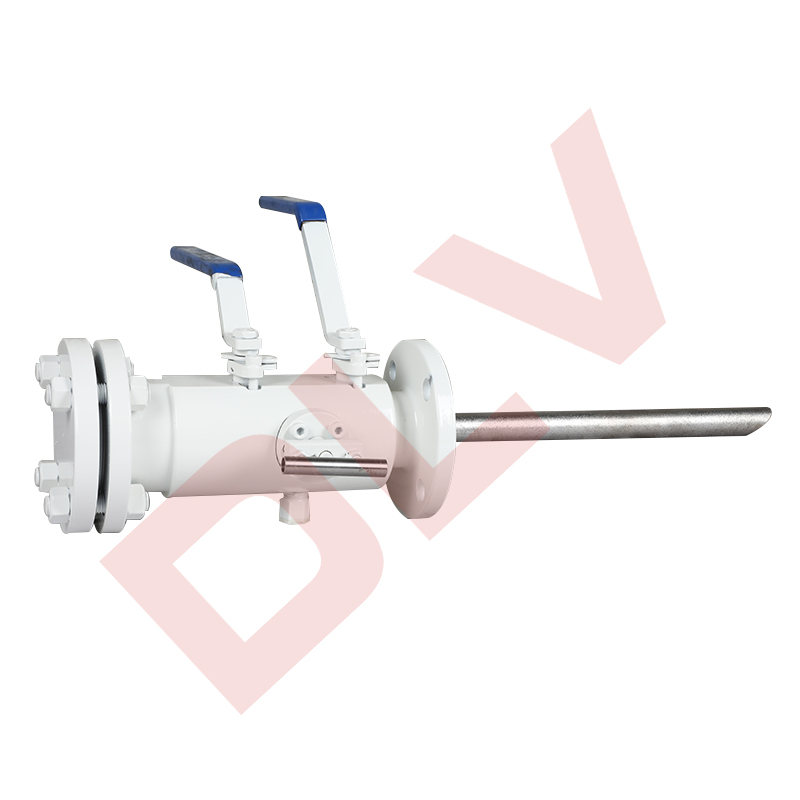

Q347F-150LB-6X4 Reduced diameter fixed ball valve

advantages

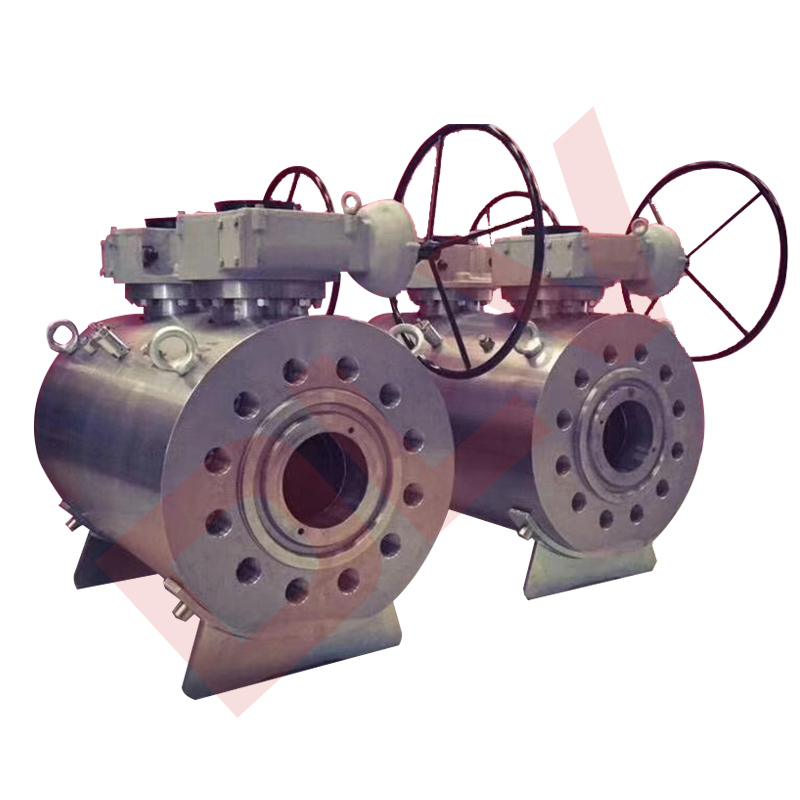

One of the significant advantages of carbon steel reduced bore fixed ball valves is their exceptional strength and durability. Carbon steel is known for its high tensile strength and wear resistance, making it an ideal material for applications where valves are subject to high pressures, extreme temperatures, or abrasive media. This rugged construction ensures the valve can withstand harsh operating conditions without compromising its functionality, providing long-term reliability and reduced maintenance requirements.

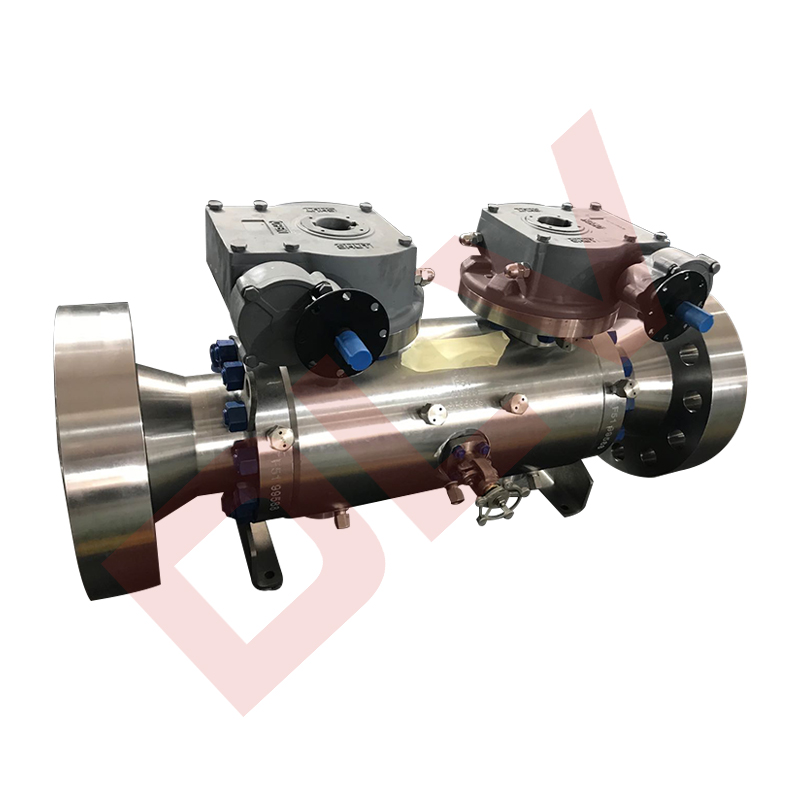

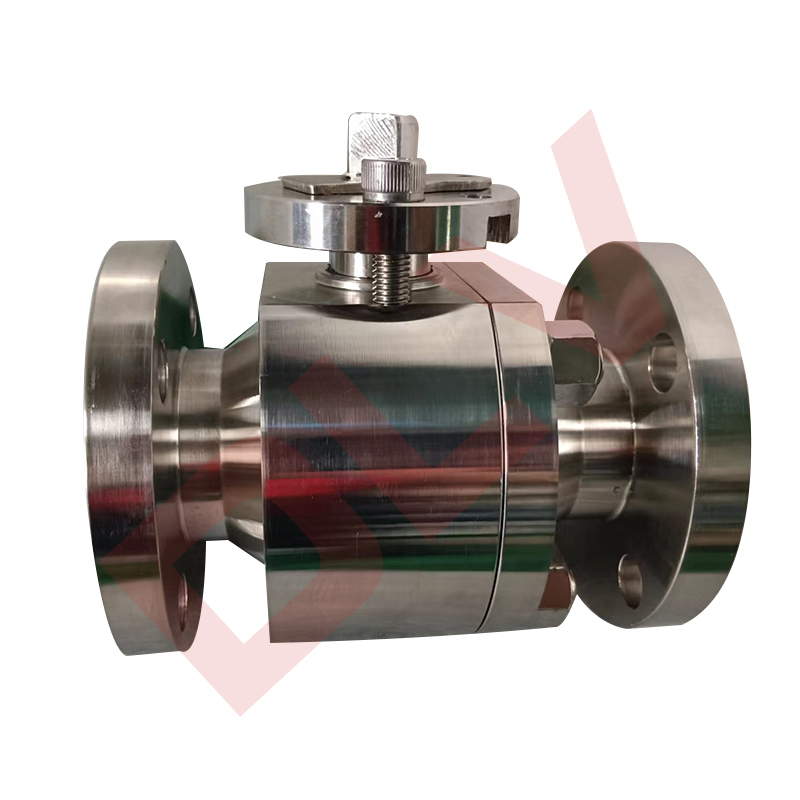

In addition to strength, carbon steel offers excellent corrosion resistance, especially when given a protective surface coating or treatment. Carbon steel valves' ability to resist corrosion and degradation caused by exposure to corrosive fluids or environmental factors ensures their suitability for a variety of industrial processes, including chemical processing, oil and gas production, and wastewater treatment. This corrosion resistance helps extend the service life of the valve and reduces the risk of leaks, failure and maintenance costs associated with premature failure. The reduced bore design of carbon steel fixed ball valves provides efficient flow control and minimal pressure drop, increasing overall system efficiency. By simplifying the flow path and reducing turbulence, the valve promotes smooth and unrestricted fluid or gas movement, optimizing operating performance and minimizing energy consumption. This design feature is particularly advantageous in applications requiring precise flow, minimal resistance and reliable shutoff capabilities, such as power plants, petrochemical facilities and pipeline networks.

description2