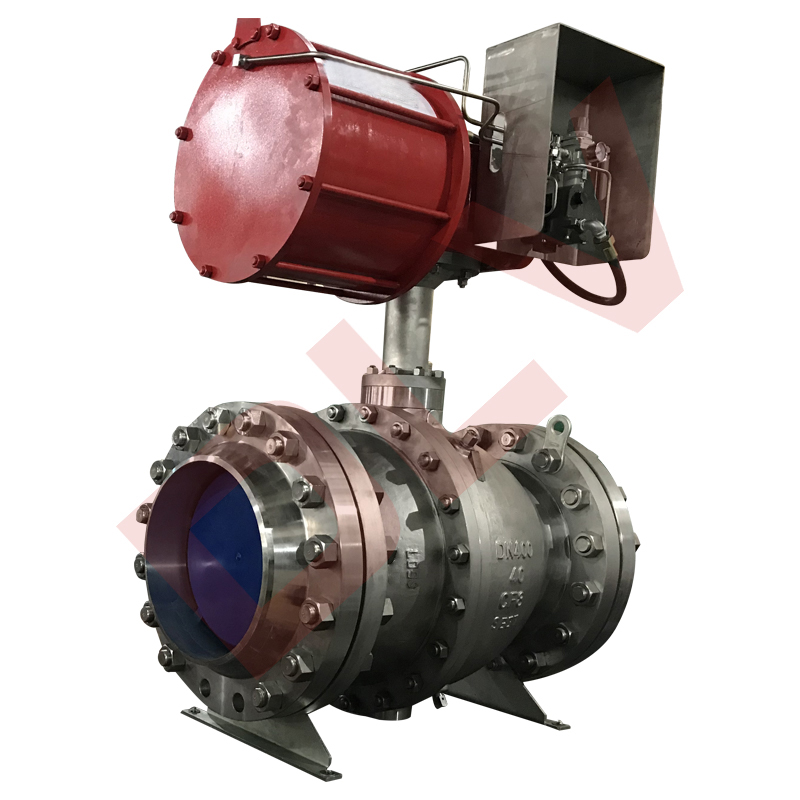

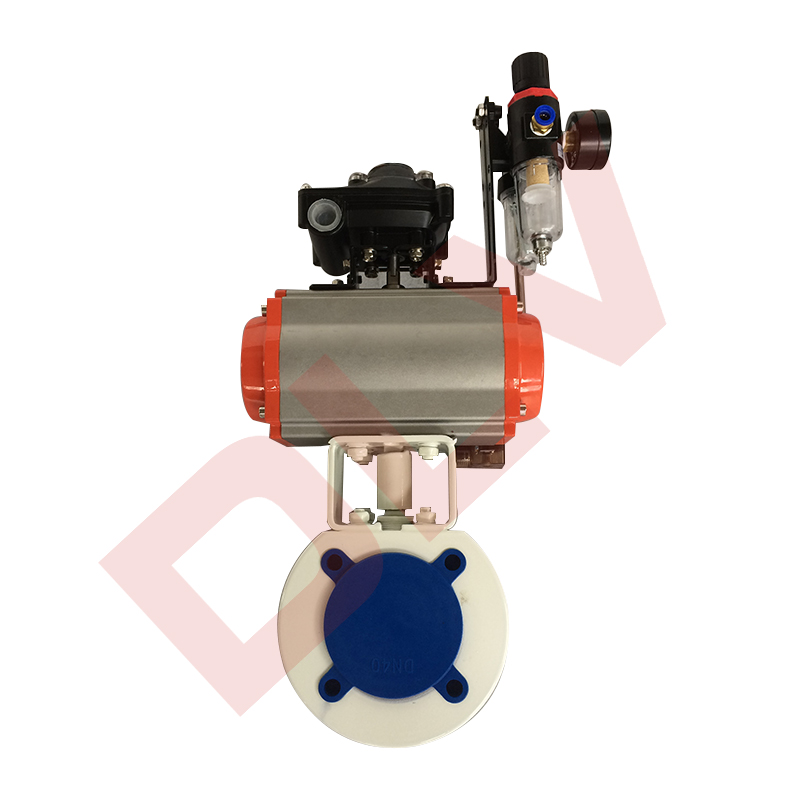

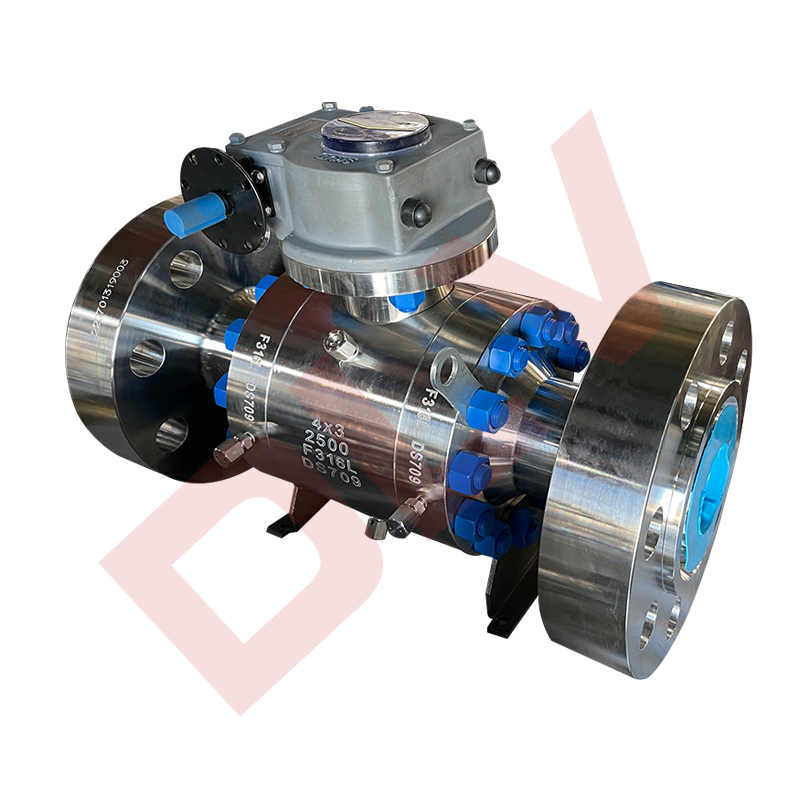

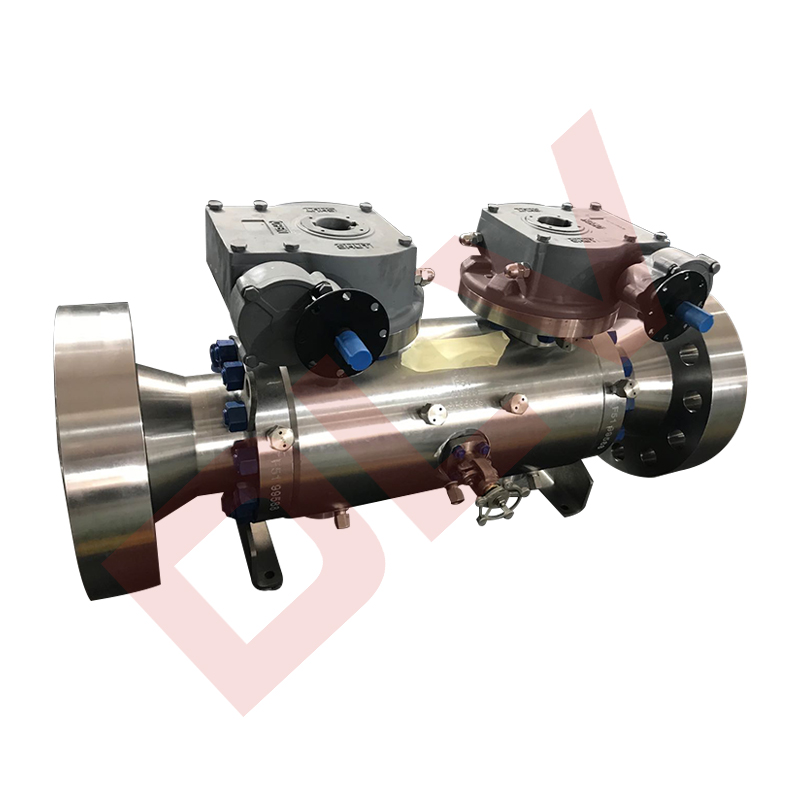

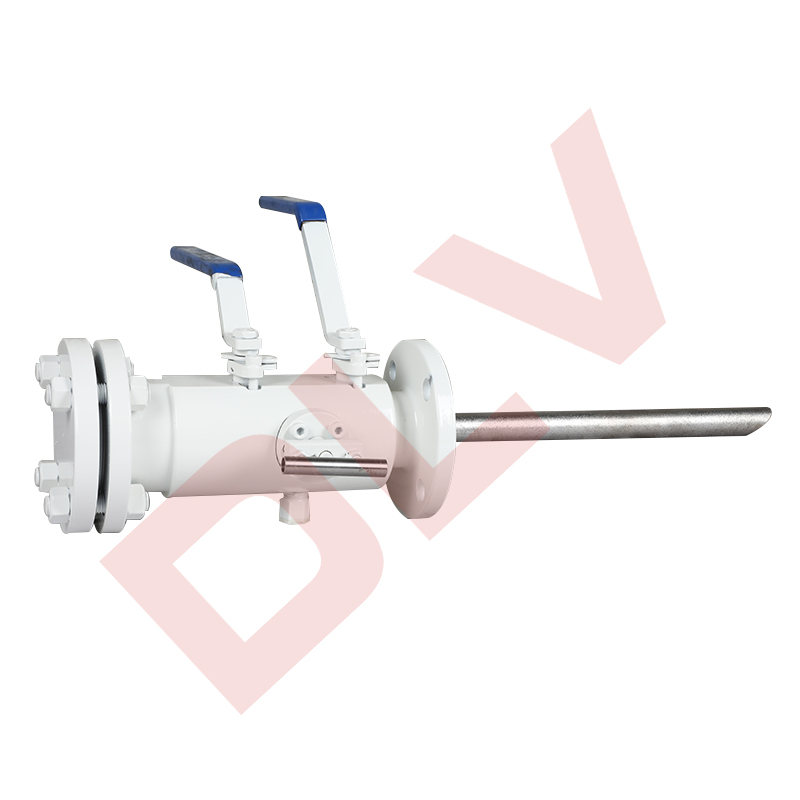

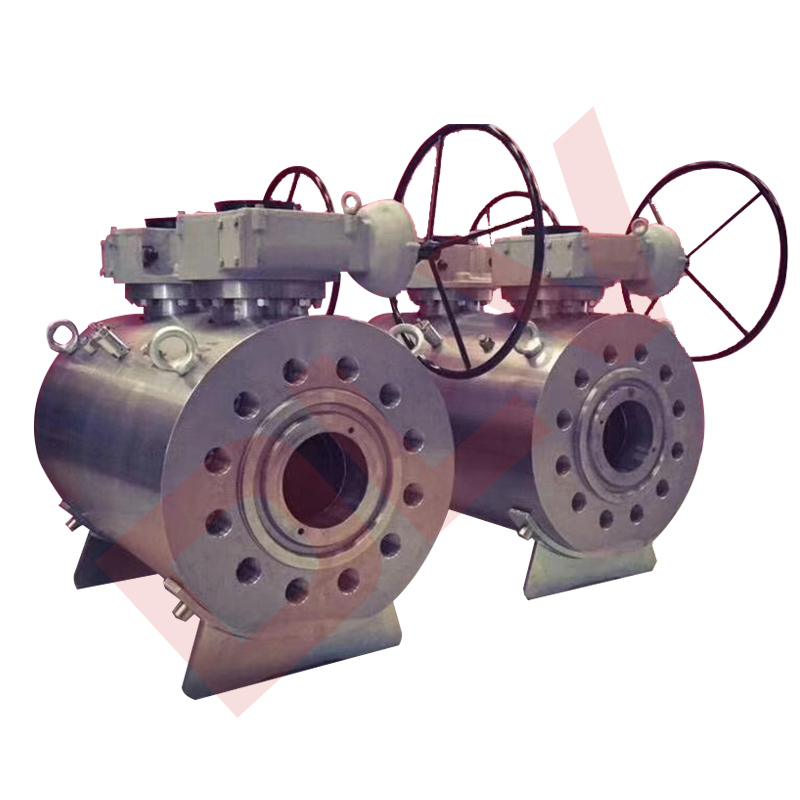

Low temperature fixed ball valve

advantages

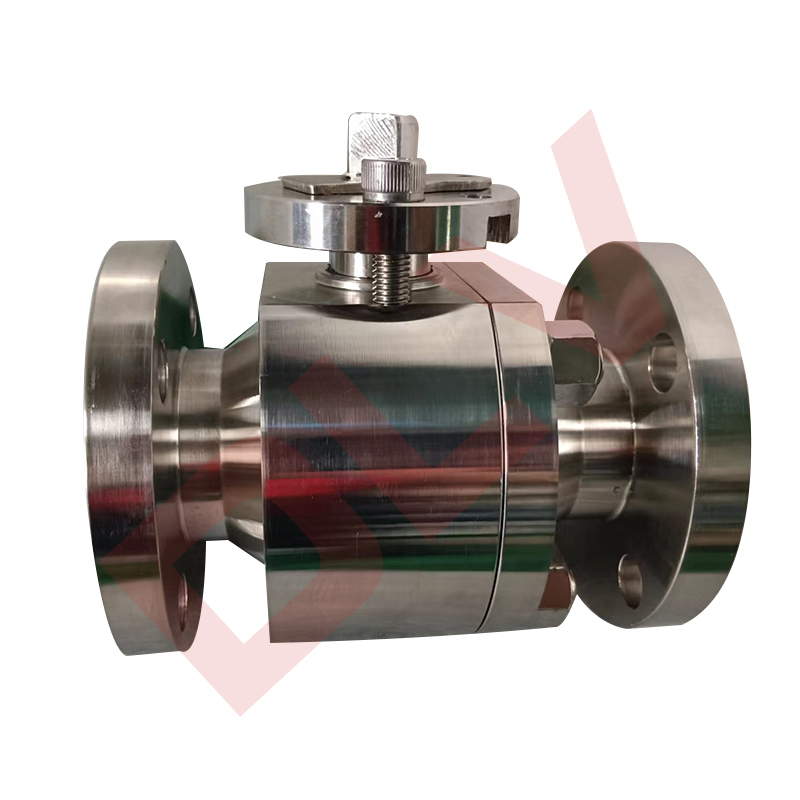

One of the main advantages of cryogenic fixed ball valves is their ability to withstand extreme cold temperatures without compromising performance. These valves are made from materials such as stainless steel or special alloys that are specifically selected for their low temperature resistance and durability. The materials used in its construction ensure that the valve maintains its structural integrity, sealing performance and operating functionality even under harsh cryogenic conditions. This reliability is critical to preventing potential leaks, valve failures and safety hazards associated with cryogenic fluid handling and transportation.

In addition to low temperature resistance, fixed ball valves designed for cryogenic applications have special features that ensure a tight seal and reliable closing even at low temperatures. The design of the valve seat and sealing components are optimized to maintain flexibility and elasticity in cryogenic environments, effectively preventing fluid or gas leakage during operation or when the valve is in the closed position. This sealing reliability is critical to maintaining cryogenic system integrity, preventing product loss, and ensuring operational safety in high-pressure and cryogenic environments.

Additionally, cryogenic fixed ball valves are engineered to provide efficient flow control and minimal pressure drop in cryogenic systems. The valve design, including bore size and flow path, is optimized to minimize flow restrictions, turbulence and energy loss, allowing for smooth and precise regulation of cryogenic fluids and gases. This efficient flow control is critical to ensure optimal system performance, avoid excessive pressure differentials, and minimize energy consumption in cryogenic processes and equipment.

In addition, the material and structure of the low-temperature fixed ball valve also contribute to its resistance to brittle fracture and embrittlement at low temperatures. These properties are critical to maintaining the mechanical strength and toughness of the valve under extreme cold conditions, mitigating the risk of material failure or loss of integrity in cryogenic applications. This resilience ensures the valve's long-term reliability and safety in cryogenic environments, reducing the need for frequent maintenance and replacement.

In summary, cryogenic fixed ball valves offer special features and advantages that make them an integral part of regulating cryogenic fluids and gases in a variety of industrial applications. Their low temperature resistance, sealing reliability, efficient flow control and anti-brittleness make them an important part of cryogenic storage, transportation and processing systems, ensuring safe and reliable handling of extremely cold media. The unique characteristics of these valves help improve the overall efficiency, safety and performance of cryogenic processes, making them a critical element of the infrastructure of industries that rely on cryogenic technology.

description2