advantages

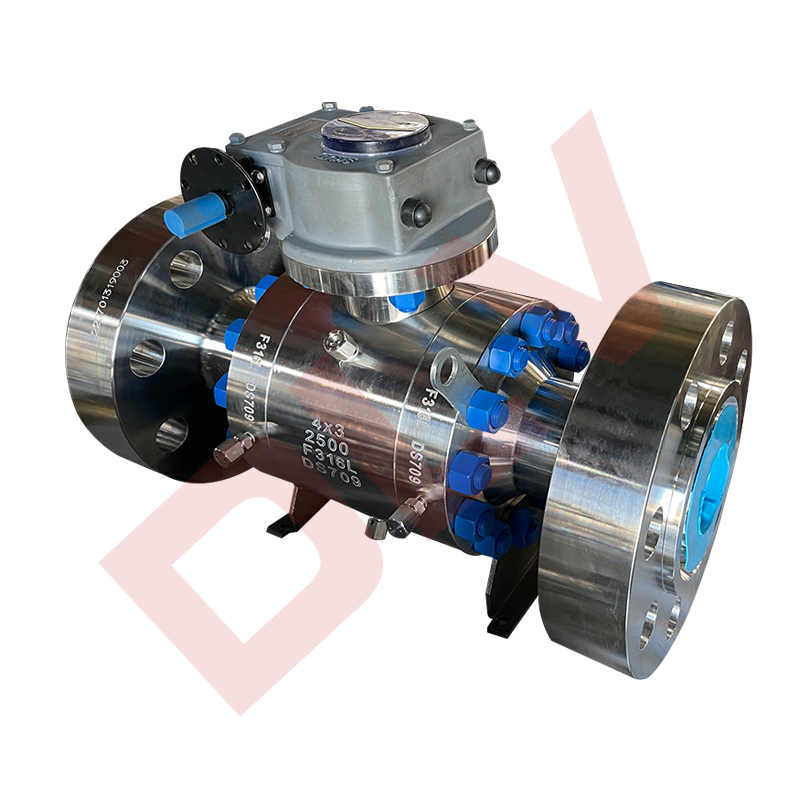

One of the main advantages of fully welded fixed ball valves is their rugged construction, which eliminates potential leak paths and ensures long-term reliability. The fully welded body design provides a seamless, leak-free construction that minimizes the risk of fugitive emissions and increases safety in critical or environmentally sensitive applications. This construction also eliminates the need for external leak points such as flange gaskets, thereby reducing the overall maintenance requirements and operational risks associated with traditional bolt-body valves.

In addition, the fully welded construction increases resistance to external environmental factors such as corrosion and erosion, making it suitable for demanding applications in offshore environments, subsea installations and pipelines carrying corrosive fluids. The absence of potential weak points such as flange connections also enhances the overall structural integrity of the valve, ensuring reliable and consistent performance even under high stress conditions.

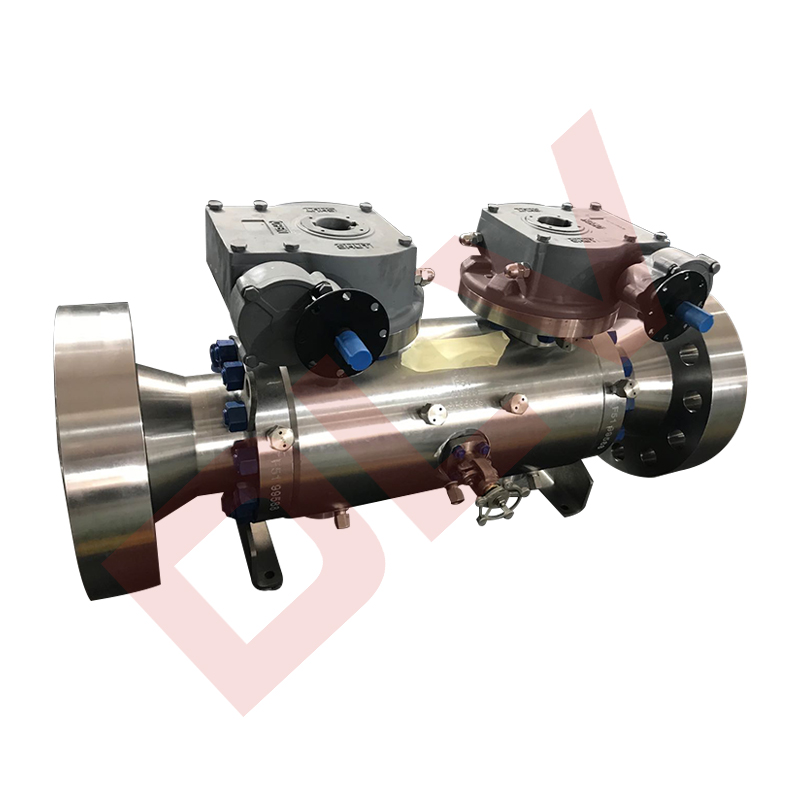

Additionally, the valve's fixed ball design provides stable and precise flow control, even in systems with high flow rates and turbulent fluid conditions. This feature is particularly useful in applications where maintaining precise flow regulation is critical to process efficiency and safety. The retaining ball design also reduces the risk of vibration-induced wear and potential damage to the seat surface, contributing to the valve's long-term durability and performance. Fully welded fixed ball valves also have the advantage of reducing installation and maintenance costs. Elimination of separate flange connections and associated sealing elements simplifies the installation process, saving time and labor during initial setup.

Additionally, the reduced potential for leaks and long valve life help reduce maintenance and replacement costs over the life of the equipment, making it a cost-effective choice for critical process applications. In summary, fully welded fixed ball valves offer several benefits, including rugged construction, enhanced safety and environmental integrity, precise flow control, and reduced installation and maintenance costs. Their ability to withstand high pressures, temperatures and corrosive working conditions makes them an essential component in critical industrial processes where reliable and long-lasting flow control is essential. The combination of advanced welding technology and expert design features ensures these valves meet the stringent requirements of modern industrial applications, providing long-term reliability and performance.