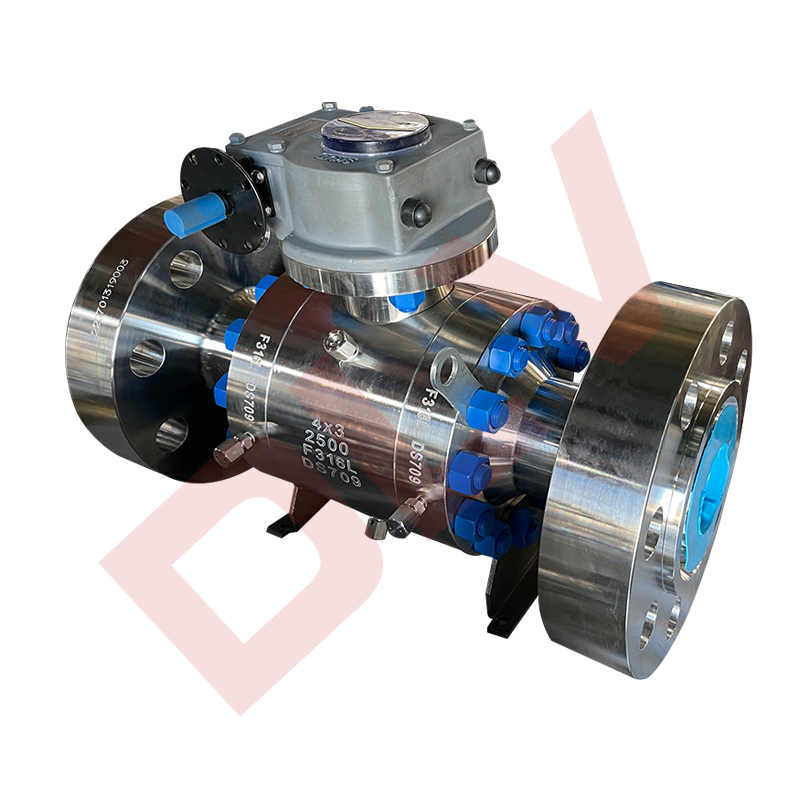

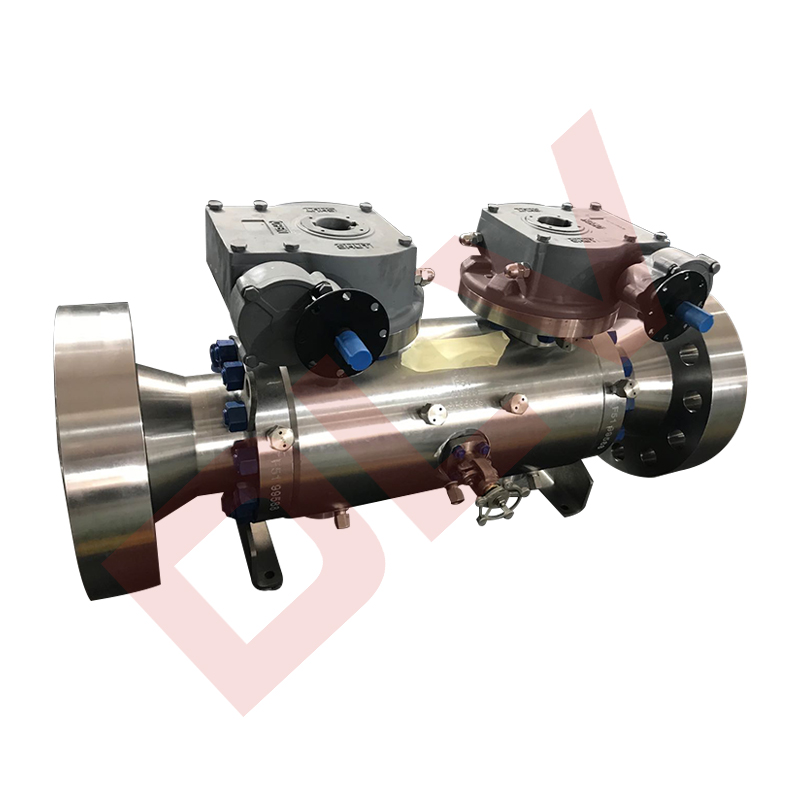

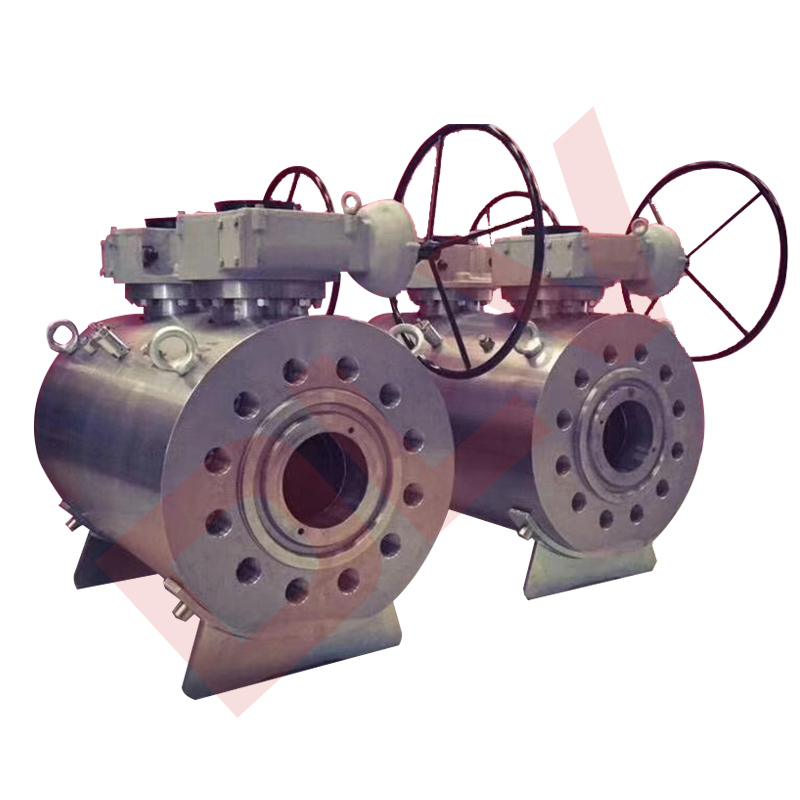

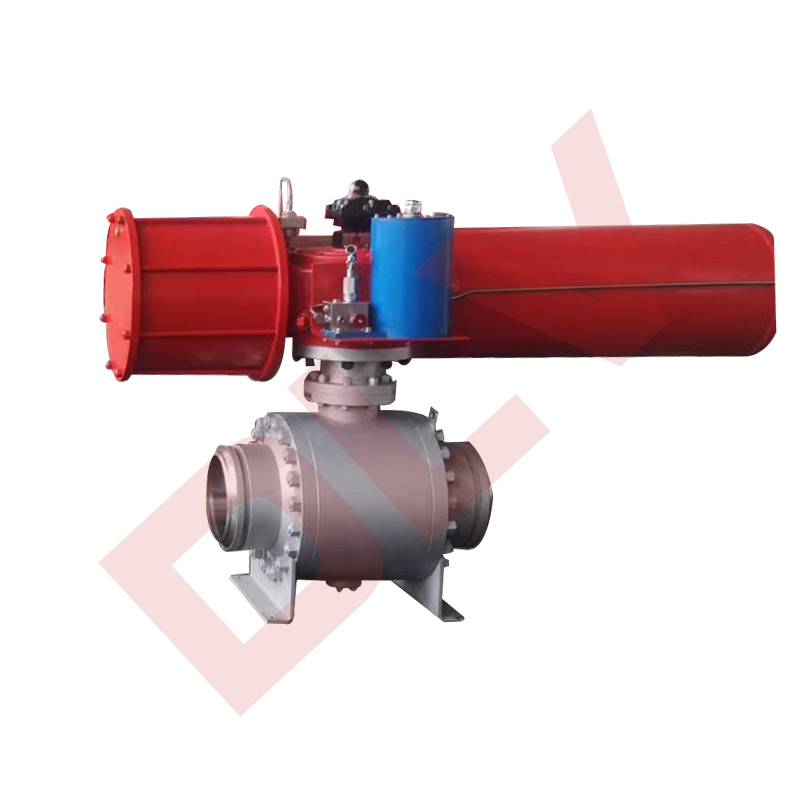

DBB floating ball valve

ADVANTAGES

1.Double barrier:

DBB floating ball valve has a double barrier design, which can effectively isolate the fluid medium and ensure that the fluid will not leak or cross-contaminate. This design provides extra security and is particularly suitable for industrial applications that require strict isolation.

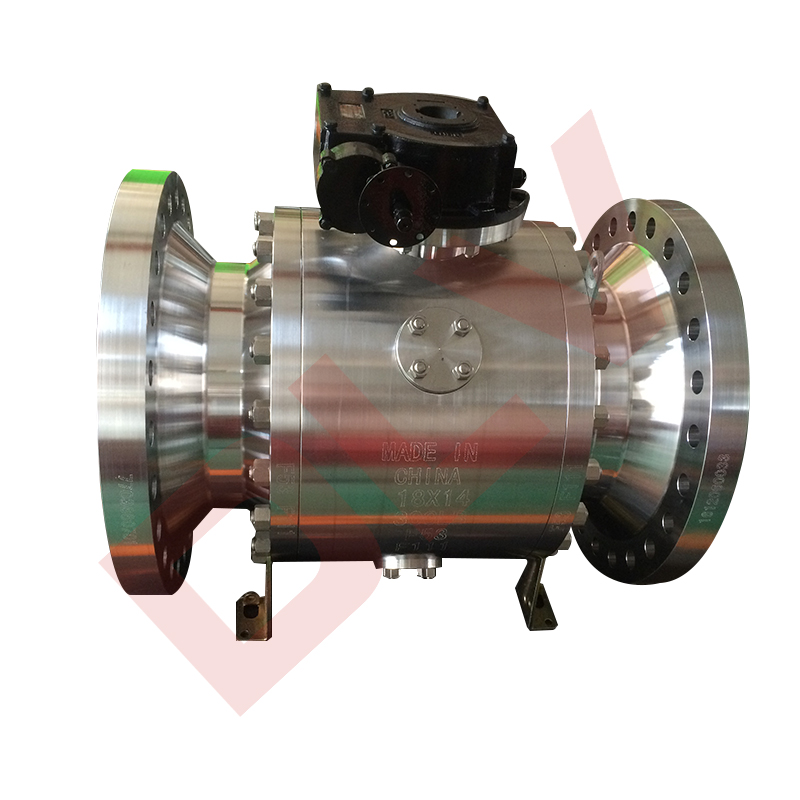

2.Built-in Pressure Relief Valve:

This type of valve has a built-in pressure relief valve that verifies the integrity of the sealing surfaces and relieves any pressure between the valve's sealing components. This helps reduce pressure build-up during operation, ensures safe operation and simplifies maintenance procedures.

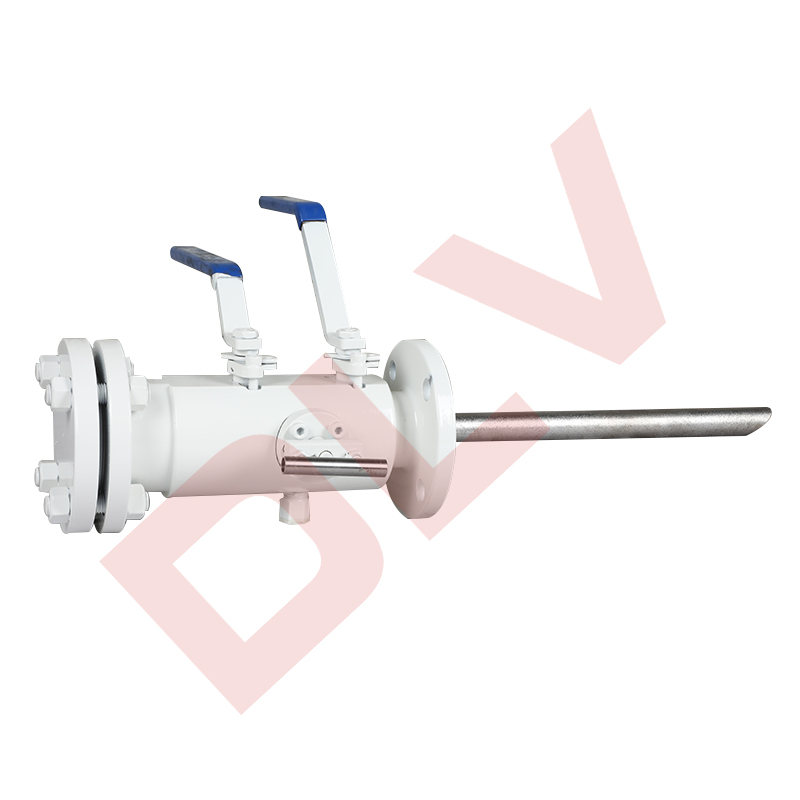

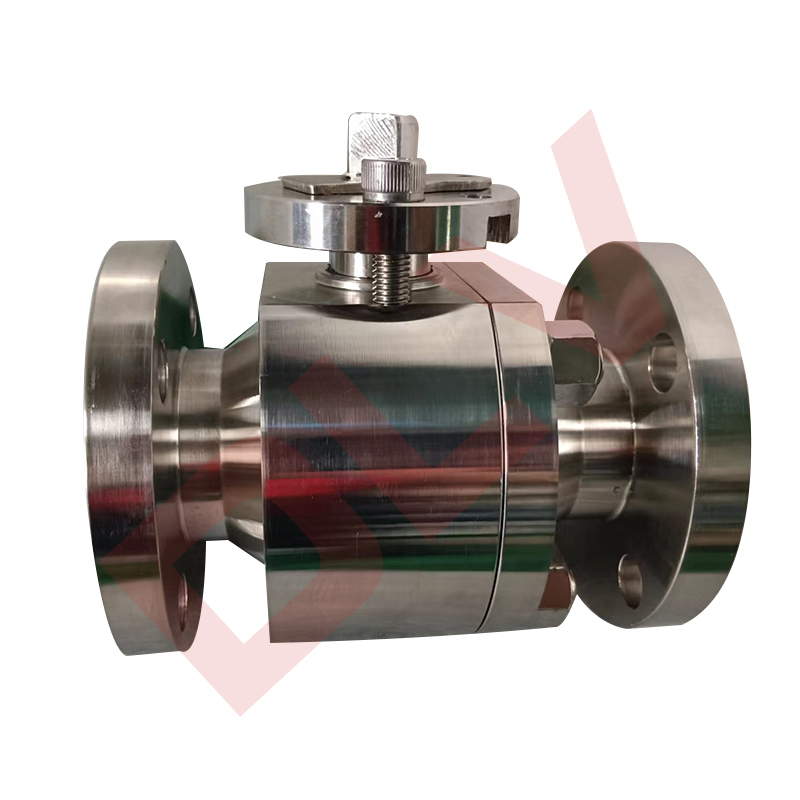

3.Floating ball design:

The floating ball design allows the ball in the valve to float slightly within the sealing ring and maintain close contact with the sealing ring, thereby achieving tight sealing under different pressure and flow conditions. This design also reduces operating torque, allowing for smoother operation and longer service life.

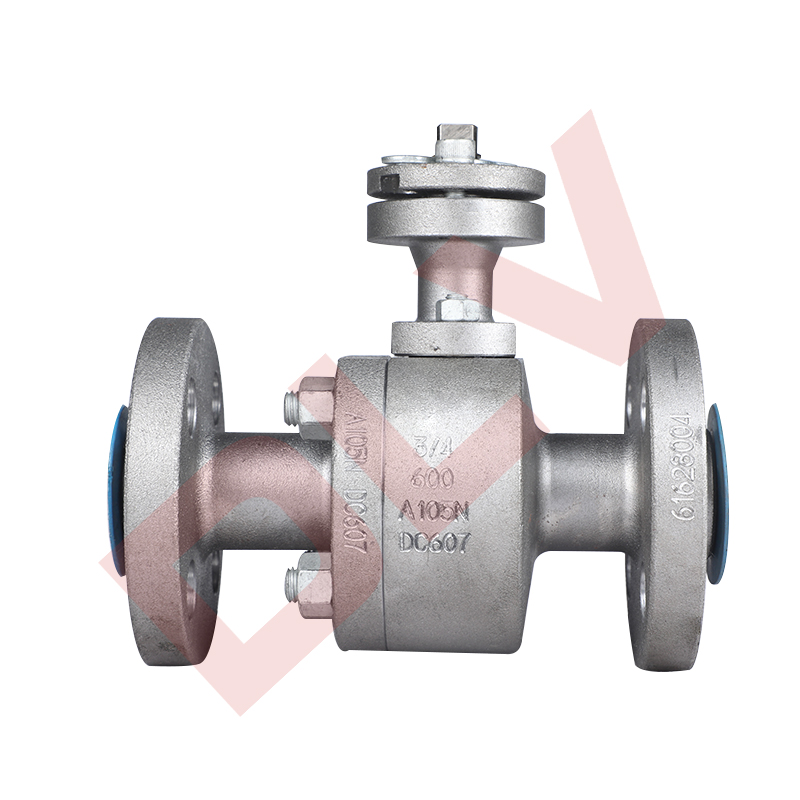

4.Multiple material options:

DBB floating ball valves can be made of a variety of materials, such as carbon steel, stainless steel and alloy steel, to adapt to different process fluids and operating conditions.

description2