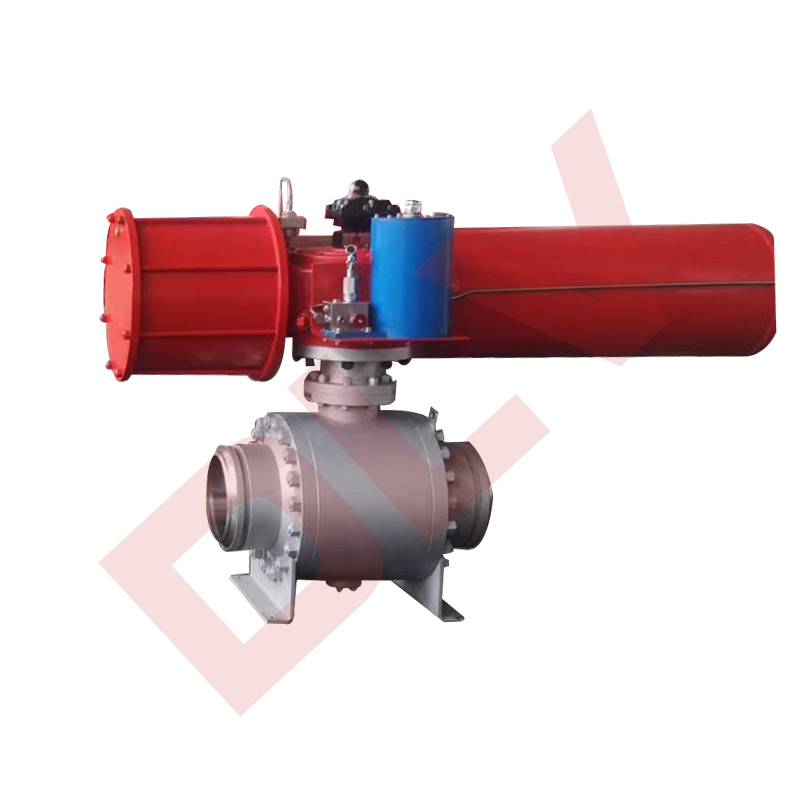

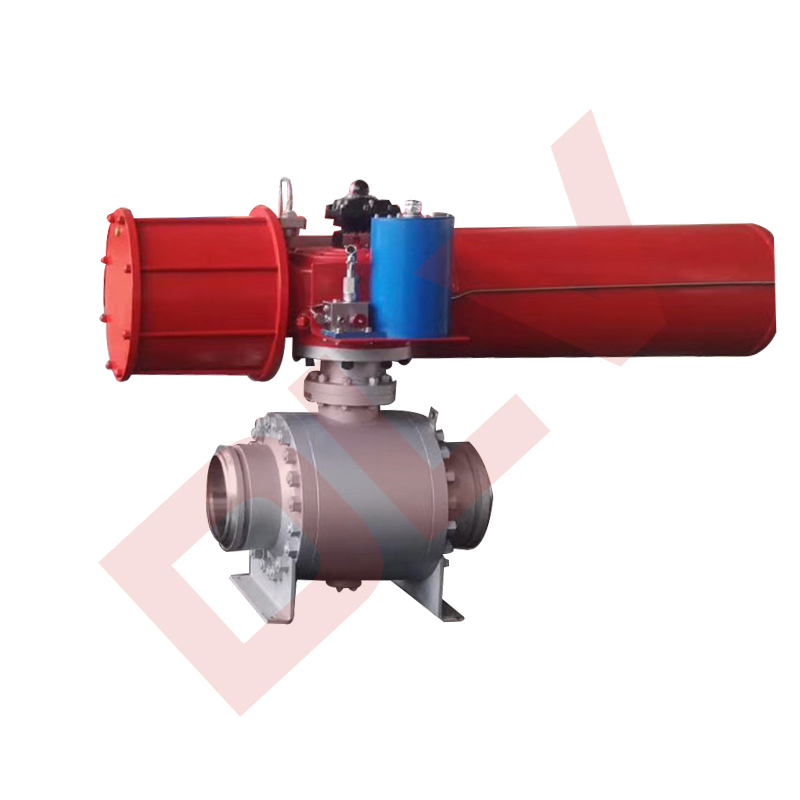

applications

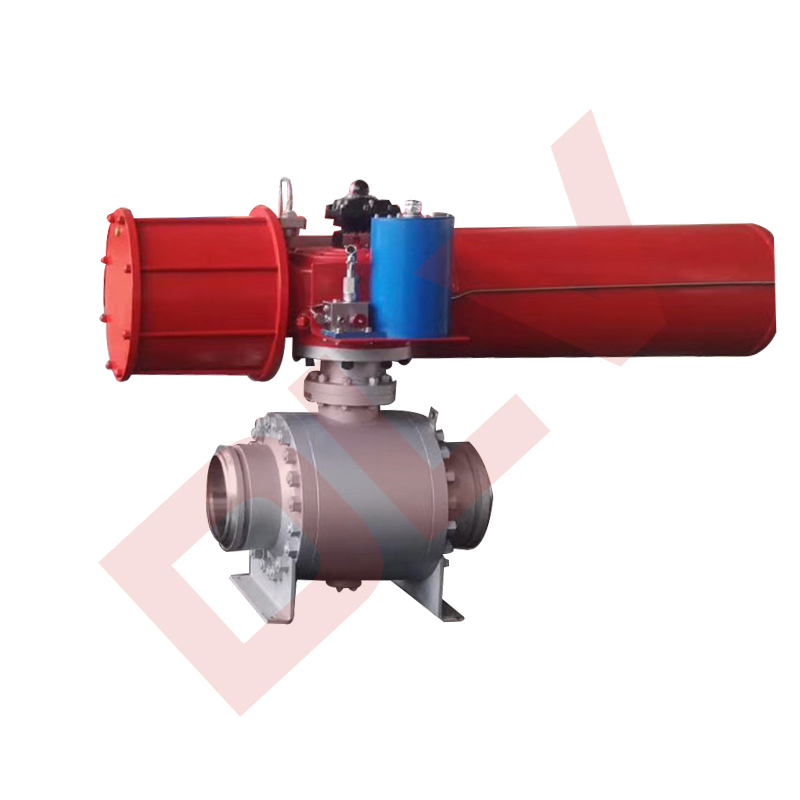

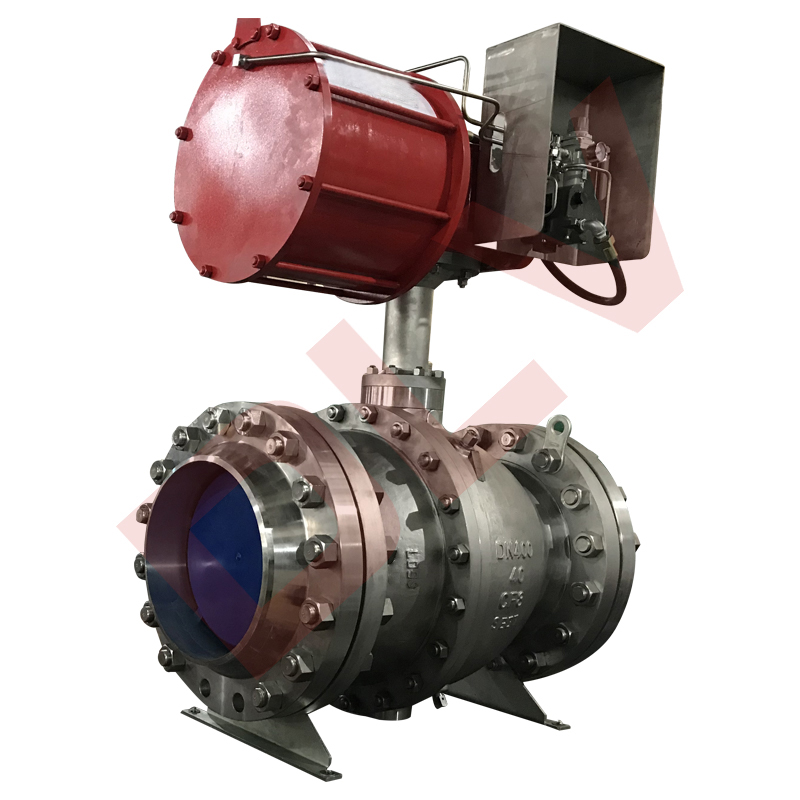

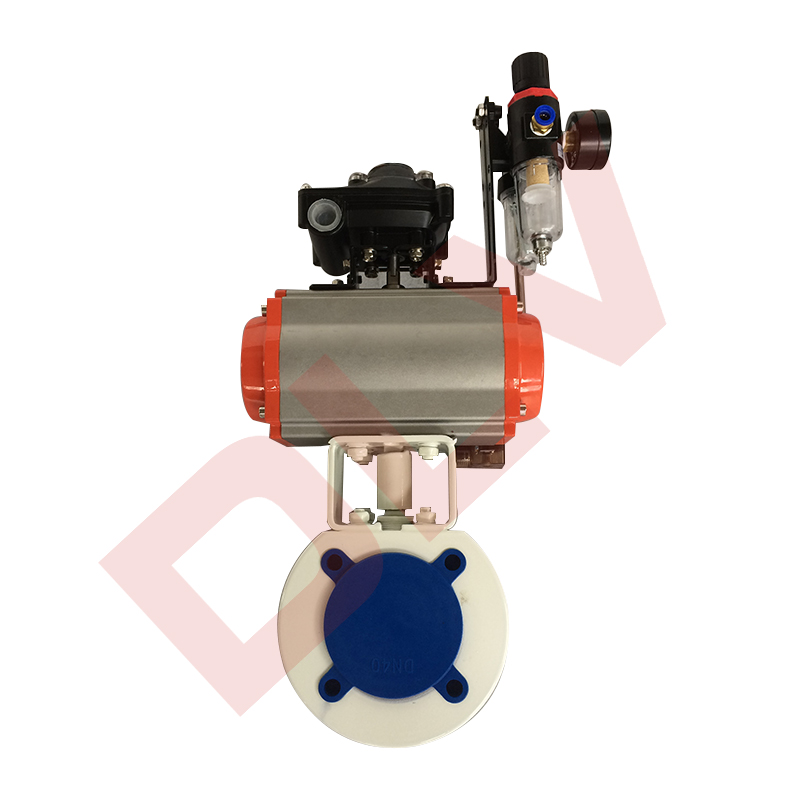

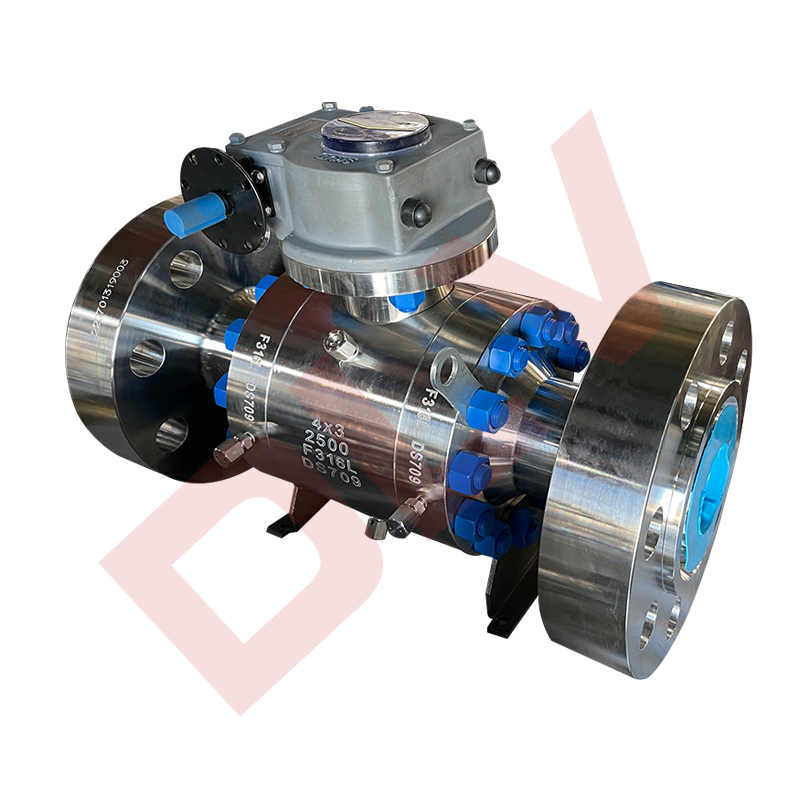

Pneumatic BW ball valves offer several advantages that make them ideal for industrial applications:

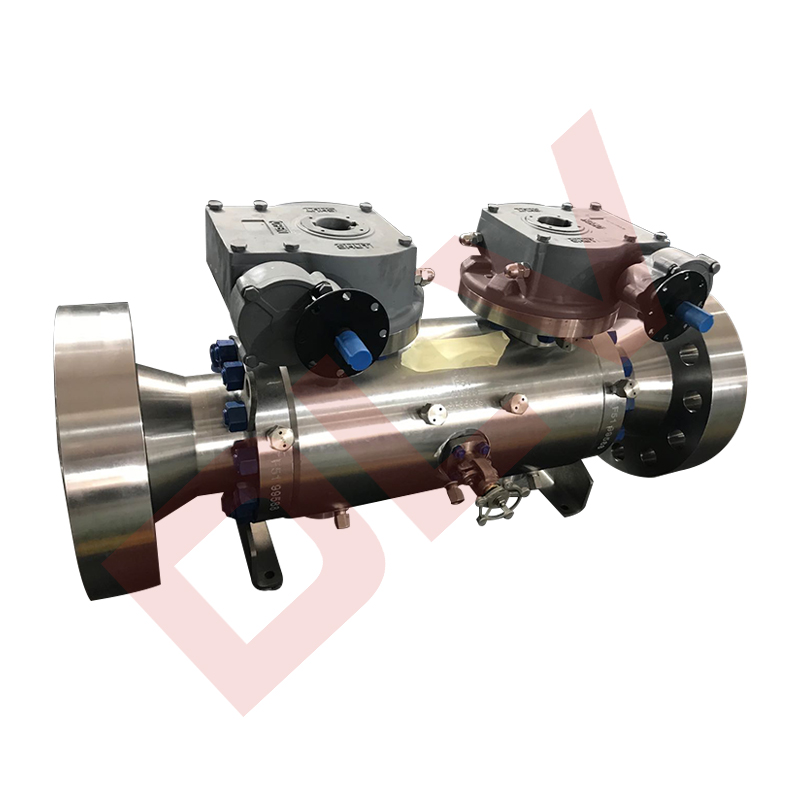

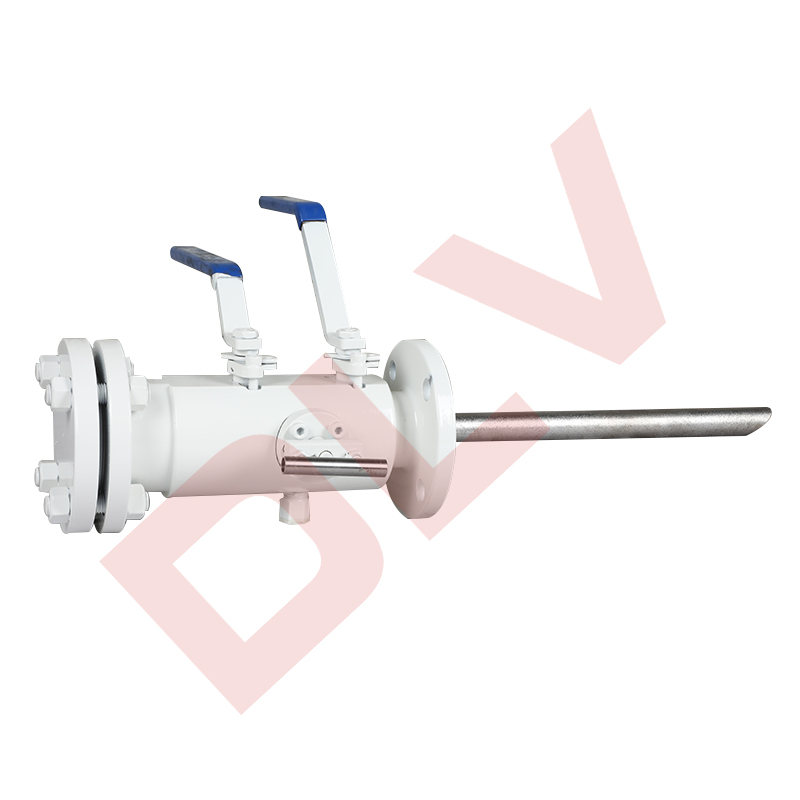

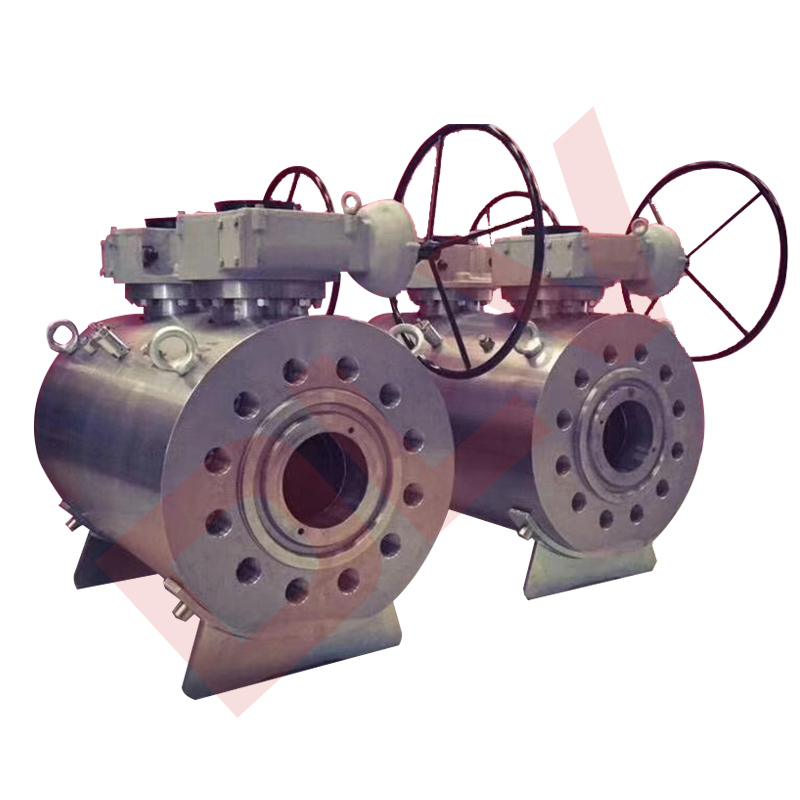

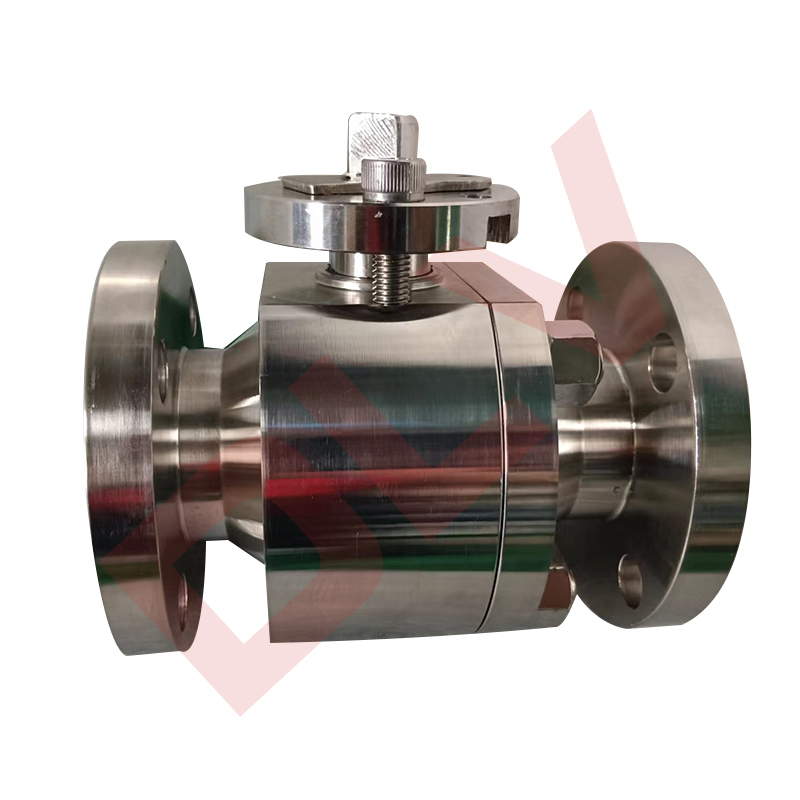

First, their pneumatic actuation provides fast and reliable operation, enabling precise control of fluid flow with fast response times. This is particularly valuable in industrial processes where flow needs to be shut down or regulated immediately to maintain operational efficiency and safety. Pneumatic actuation also eliminates the need for manual operation, reducing the risk of operator fatigue and ensuring consistent performance during long runs. The butt weld connection of these valves provides a strong and leak-free connection between the valve and pipe. This enhances the overall integrity of the system, ensuring there are no potential points of failure or leakage. Welded connections also facilitate easy integration into pipes, providing a secure and permanent connection that can withstand the rigors of industrial environments, such as high pressures and temperature fluctuations.

Additionally, the welded construction minimizes the risk of corrosion and external damage, contributing to the valve’s long-term reliability.

Additionally, the design of the pneumatic BW ball valve allows for bi-directional flow control, allowing for versatile operation in both upstream and downstream directions. This flexibility is advantageous in applications where flow direction may need to be reversed or adjusted, thereby providing efficient and reliable regulation of fluid motion. Pneumatic BW ball valves are capable of handling a wide range of fluids, including corrosive and abrasive media, making them suitable for use in a variety of industrial processes such as chemical processing, oil and gas production, power generation and water treatment.

In summary, pneumatic BW ball valves offer significant advantages, including fast-response actuation, durable butt-weld connections, and versatile bidirectional flow control. Their ability to withstand harsh operating conditions and accommodate a wide range of fluids makes them an important component in industrial systems that require precise and reliable flow regulation. The combination of pneumatic actuation and welded construction ensures these valves meet the demanding requirements of modern industrial processes, helping to increase operational efficiency, safety and service life.